Solar PV cells are usually square-shaped and measure 6 inches by 6 inches (150mm x 150mm).

There are different configurations of solar cells that make up a solar panel, such as 60-cell, 72-cell, and 96-cell.

The most common solar panel sizes for residential installations are between 250W and 400W.

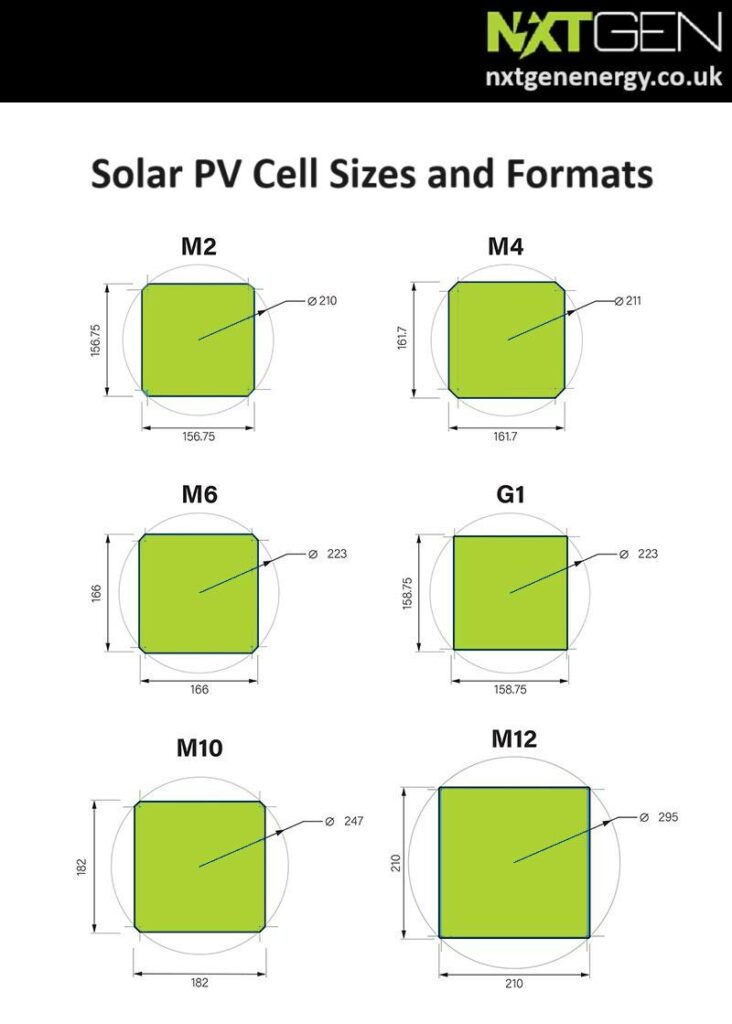

The Solar Cell Size Chart below shows the different types of solar photovoltaic (PV) cells that are available on the UK market today. Solar PV cells are devices that convert sunlight into electricity. They are made from silicon (Si), which is a semiconductor material that can absorb light and generate electric current.

Monocrystalline and Polycrystalline Cells

There are two main categories of solar PV cells: monocrystalline and polycrystalline. Monocrystalline cells are made from a single crystal of silicon, while polycrystalline cells are made from multiple crystals of silicon. Monocrystalline cells have higher efficiency and durability than polycrystalline cells, but they are also more expensive and difficult to produce.

Solar PV Cell Shapes

Monocrystalline cells are produced by cutting thin slices or wafers from a cylindrical ingot of silicon using a laser. The shape of the ingot determines the shape of the cell. If the cell is cut as a perfect circle, it will have the least amount of silicon waste, but it will also leave gaps between the cells when they are arranged in to a solar panel. These gaps reduce the power output of the solar panel, because they do not capture any sunlight.

To increase the power output of the solar panel, solar PV manufacturers try to fill the gaps between the cells by cutting them into different shapes. One common shape is a square with rounded corners, which is called an M2 cell. This shape has a size of 156.75 mm x 156.75 mm (6.17 in x 6.17 in) and has been widely used in the industry for a long time.

Larger Solar PV Cell Sizes

However, as silicon prices have fallen, manufacturers have found it more profitable to cut the cells into larger and more square shapes, which can cover more area in a panel and generate more electricity. This has led to the emergence of various new cell formats, such as M4, M6, G1, M10, and M12. Each format has a different size and edge length, ranging from 161.7 mm (6.37 in) to 210 mm (8.27 in).

Solar PV manufacturers have officially started efforts to establish a new ‘M10’ (182mm x 182mm (7.2 in x 7.2 in) p-type monocrystalline) large-area wafer size standard to reduce manufacturing costs throughout the related solar industry supply chain as the number of large-area wafer sizes have emerged in the last few years.

No Standards for Solar PV Cell Sizes

The problem with having different cell formats is that they also result in different panel sizes. This means that the industry has lost the standardization and compatibility that it had with the M2 cell size format. This can ultimately affect the installation, transportation, and maintenance of solar panels in the future. Therefore, some experts argue that the solar PV industry should agree on a common solar PV cell size and format to avoid confusion and inefficiency.

Conclusion

You now know the different types of solar PV cells and how their shapes and sizes affect the power output and efficiency of solar panels. But the big problem comes from losing standardization and compatibility in the industry due to the different cell formats, and the solar industry should agree on a common PV cell size and format to avoid confusion and inefficiency.

Feeling motivated and ready to switch to solar? Want to learn more? Your best option is to talk to one of our friendly solar energy experts on 01268 928 690 or click on the button below and we will help you find the right fit for your home and budget.

Solar PV Cell Sizes and Formats

Solar PV Cell Sizes and Formats